A Norwegian company has developed a new type of fuel tank for liquid hydrogen. It is welded together – robots.

Norwegian IC Technology has developed a technique to build a prism-shaped fuel tank that can hold liquid hydrogen at minus 253 degrees Celsius without actually boiling.

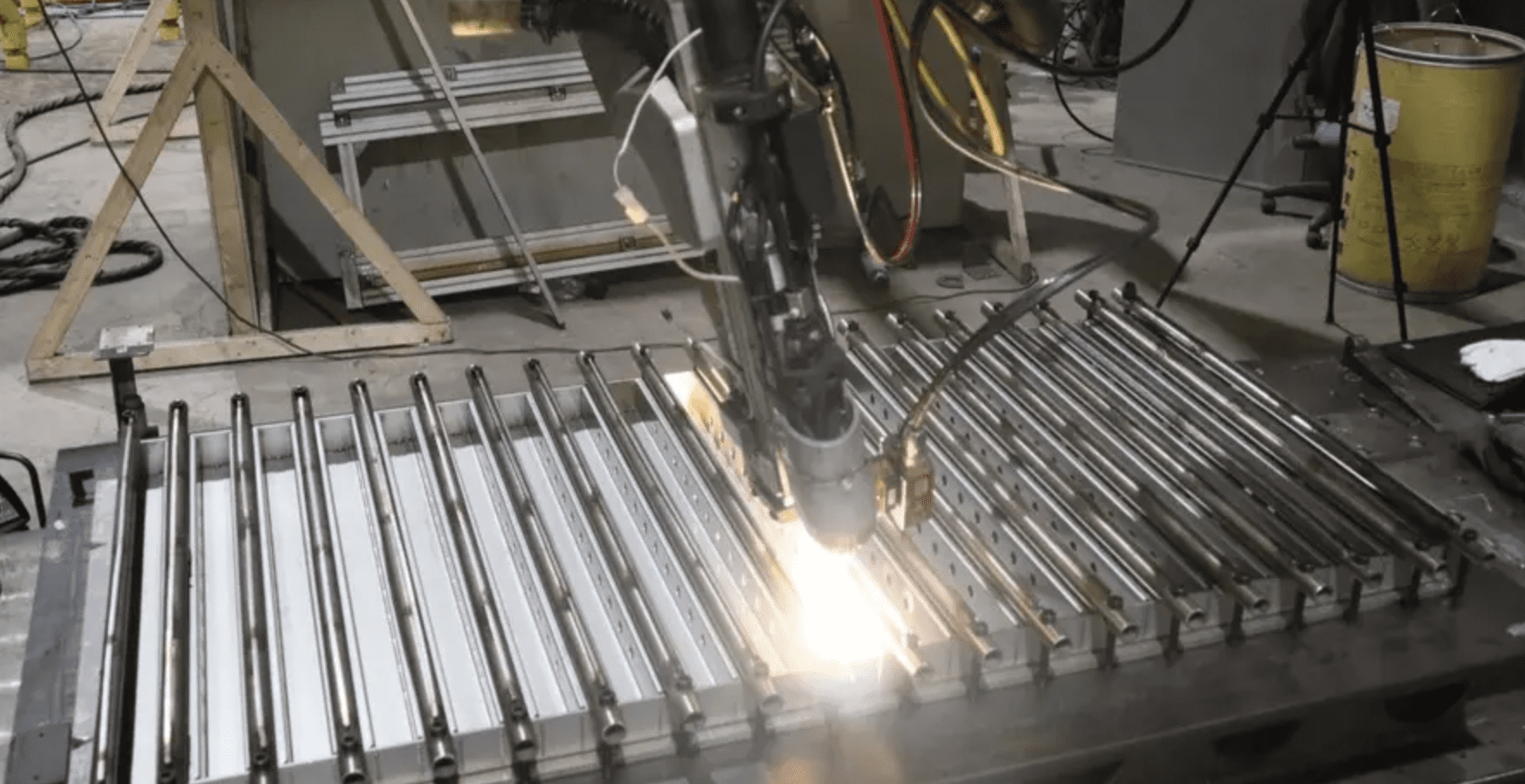

Assembly of the full-scale tank began with robots laser welding the main components of the 2 cubic meter prototype at Prodtex in Fisca, Norway. The plan is to test the concept at the IFE (Institute for Energy Technology), a research institute in Kjeller outside Oslo.

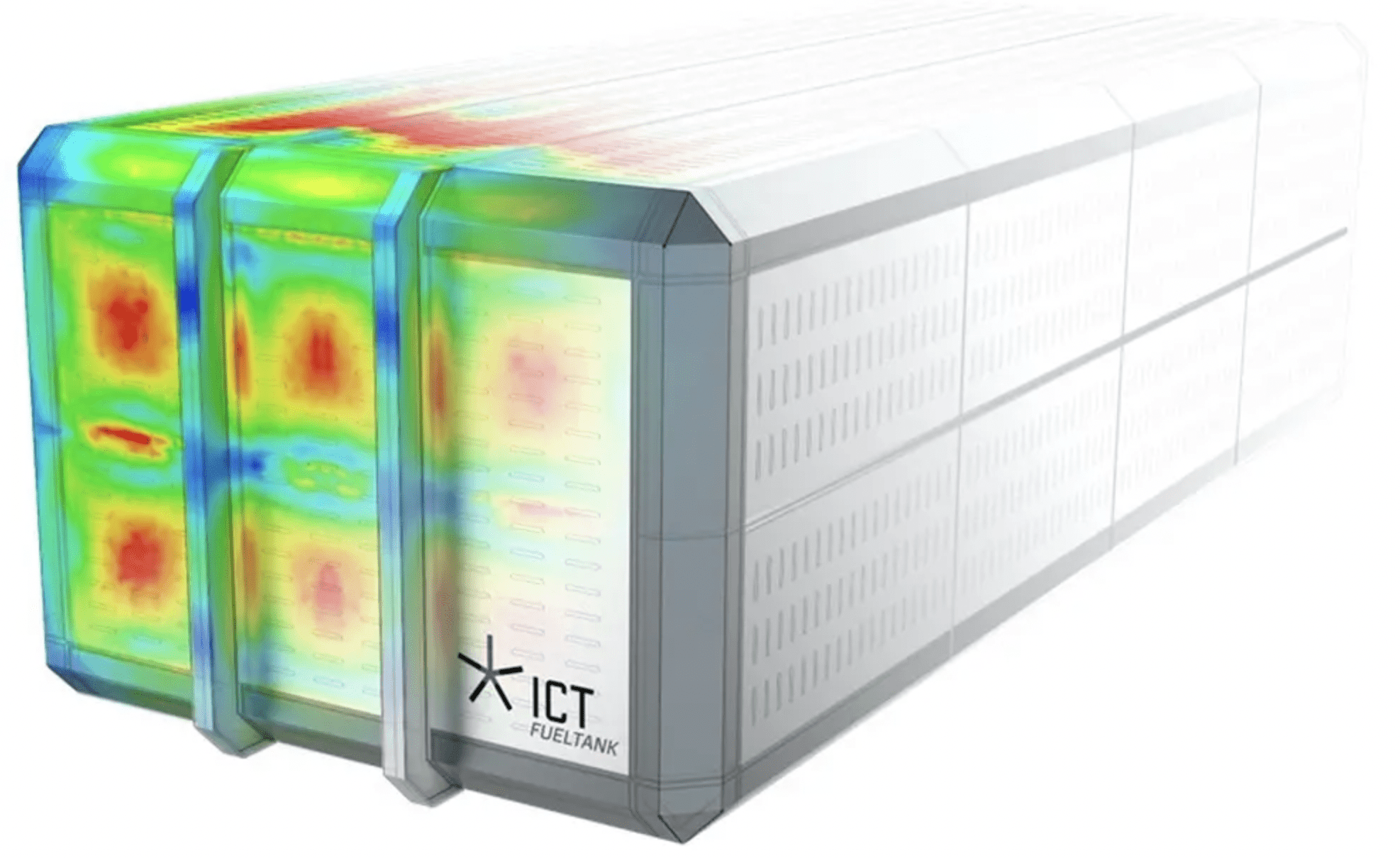

ICT’s hydrogen tanks have sensors that monitor leakage, temperature and wear. A digital twin is used to monitor wear and tear. Illustration: I.C.T

The marine sector is leading the development, but the tank can also be used on land, says IFE CEO Leve Lett.

– This tank can have many uses. We have chosen to focus on areas where projects have progressed and which seem to be for marine use, says Leiv Låte.

The tank is developed by connecting a scalable and flexible modular system with a capacity of up to 10,000 cubic meters.

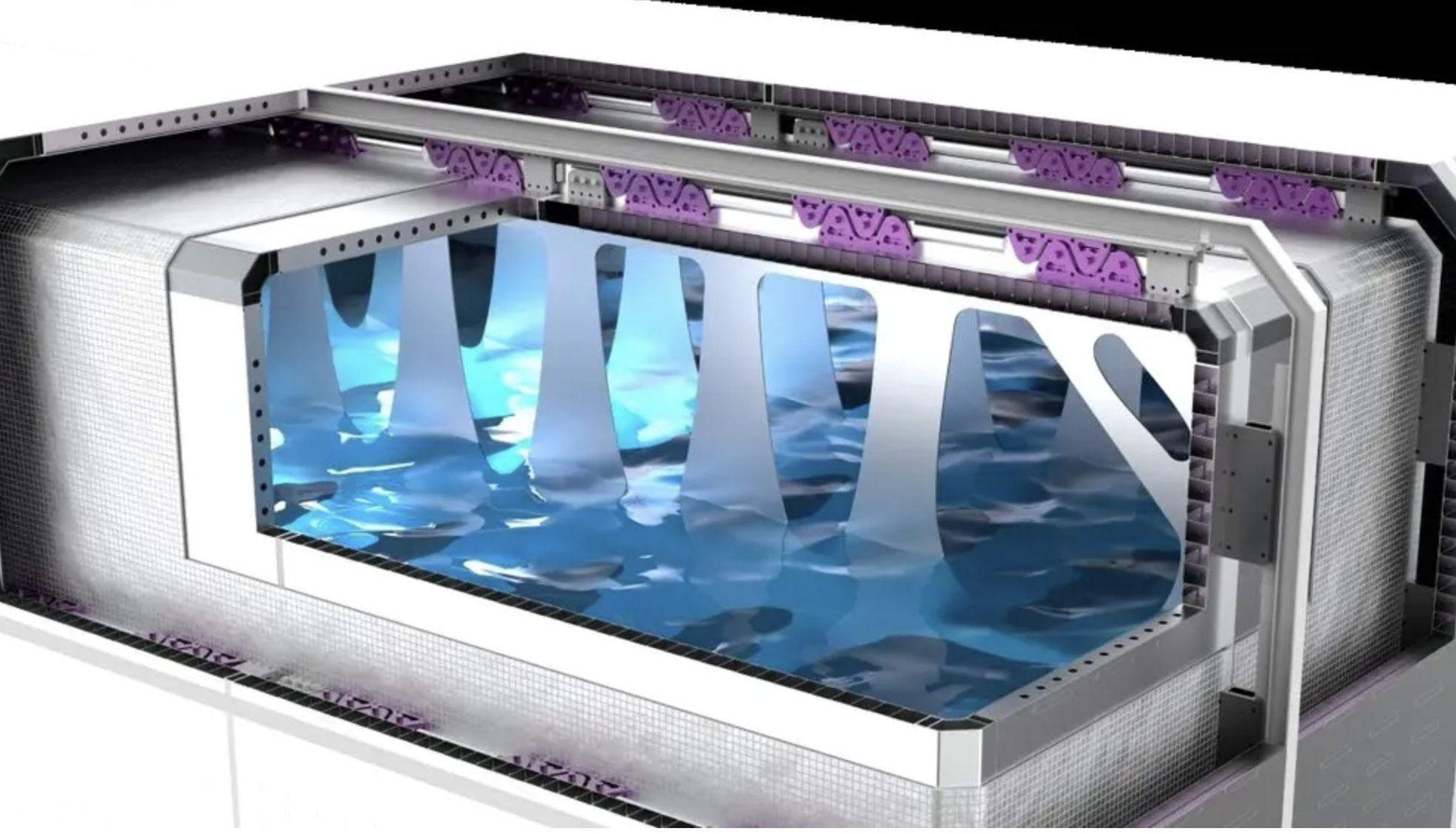

It is designed as a prism-shaped, self-supporting tank-in-tank made from thin stainless steel plates. The inner and outer tanks are built in several layers with a vacuum in a sandwich material. There is a high vacuum between the inner tank and the outer tank.

High vacuum for insulation

Between the tanks there is a temperature compensation in a special composite material and a specific design. They are designed to create the smallest possible cold bridge or heat transfer. They act as a physical support between the tanks when the innermost tank shrinks when filled with liquid at minus 253 degrees.

By using high vacuum for insulation, boiling (loss through evaporation) is reduced.

The tank is set up and designed so that any leaks can be detected and detected immediately.

Leiv Låte says thermal cycling is what “wears” the tank, meaning the tank fills and empties. Hence monitoring is required.

– We will develop a digital twin where we can retrieve the data from the tank and keep it intact and plan the tests, says Låte.

In addition to the tanks, the plan also includes a vaporizer system that converts liquid hydrogen into hydrogen gas at a temperature of about 20 degrees. The hydrogen is then fed into a fuel cell.

The tank system can in principle be used for other gases that must be cooled to liquefy, above all ammonia (NH3) and liquefied natural gas (LNG).

– Challenges there are weight and ammonia corrosiveness. But it’s manageable, says Leave Let.

Prodtex has developed the welding robots used for the panels in the ICT tank. Photo: ICT

Another challenge that can be tackled is classification rules and flag states (the country where a ship is registered).

– Our tank does not exactly fit the current standards and regulations. We have a dialogue with the shipping authorities and the DNV classification society.

He believes IC Technologies’ solution can be tailored and tailored for optimal use of space.

This is something that the ship designers at LMG Marine place great importance on.

– Prism-shaped tanks open up a more flexible design, says LMG Marin CEO Torbjörn Bringedal.

Are fuel cells and batteries a good combination?

Norwegian fuel cell company Corvus Energy believes that fuel cells and batteries are the perfect combination. The company is partnering with Toyota, which supplies fuel cells. Corvus is developing Toyota’s fuel cells for marine use. A new test facility for propulsion systems with hydrogen-powered fuel cells and batteries recently opened.

Thor Hummerfelt, director of fuel cell systems and architecture, says IC Technology’s tank system looks promising.

– It would be good if we could develop a supply chain as complete as possible in Norway. “We need suppliers of fuel tanks and conditioning systems that deliver hydrogen at the right temperature and pressure for a fuel cell,” says Humerfelt.

Among the largest owners is Saga Pure, the company of financier Oystein Strey Spatelen. The company invests in what it calls “future winners of the green transition.”

CEO Björns Simonsson has many years of experience with hydrogen from electrolyzer manufacturer NEL. He strongly believes in IC technology.

– We invest in companies with green technology that help create more jobs. IC technology is one of them. A new generation of storage tanks is needed for liquid hydrogen storage without loss through boiling, says Simonsen.

Article first published Tekniks Ukebladand made available to Ny Teknik’s readers through collaboration between newspapers.

Prone to fits of apathy. Unable to type with boxing gloves on. Internet advocate. Avid travel enthusiast. Entrepreneur. Music expert.