Robotic arms have gone through rapid growth phases throughout the years. As a result, these machines have accrued an astounding range of features, making them better at executing any tasks thrown at them.

At the same time, even as these machines have enjoyed rapid technological advancements over the last decade, the costs of the crucial components in these machines have fallen drastically. These have seen a huge uptake of robotic arms in a wide range of sectors, including production.

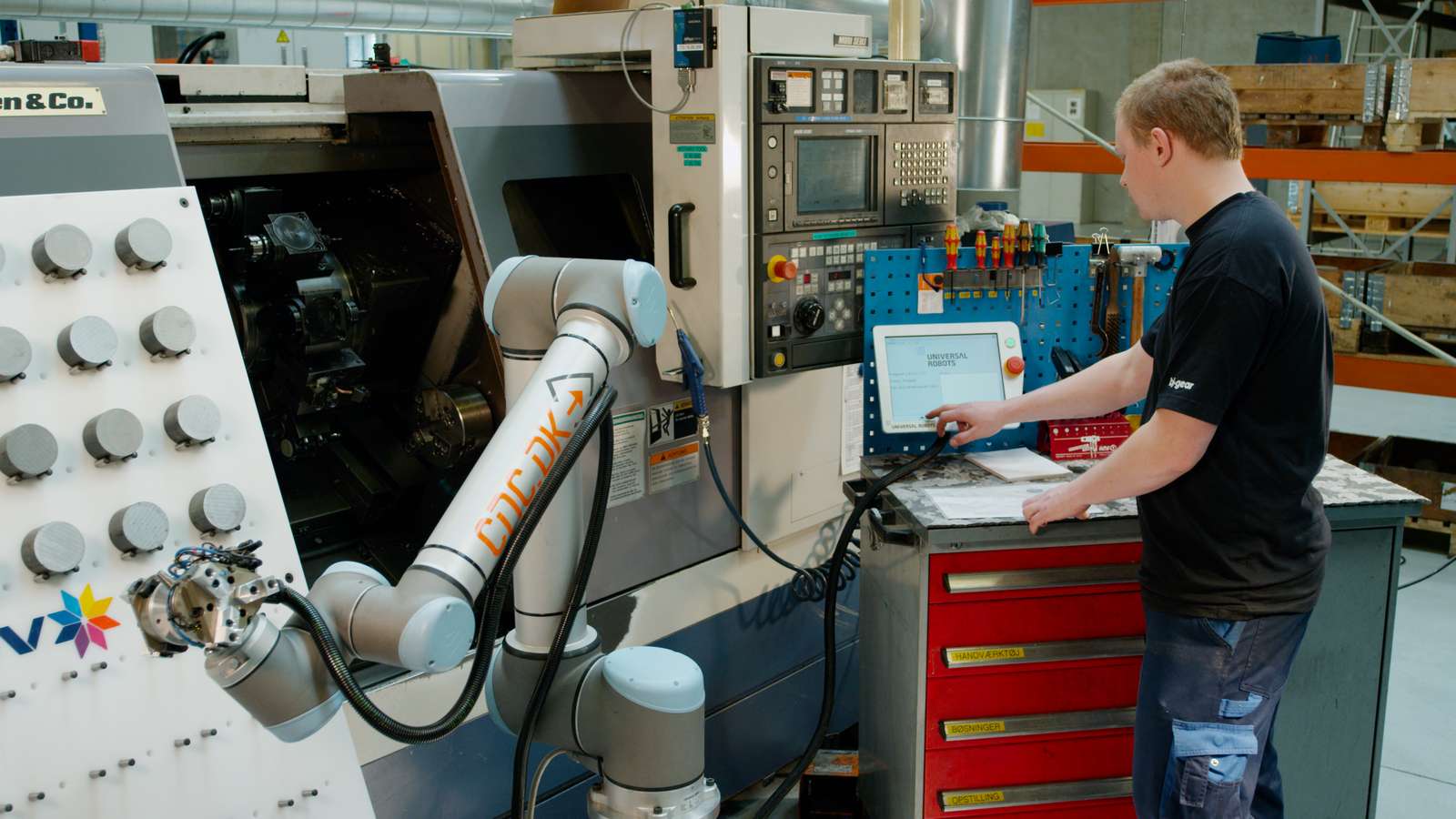

Today you’ll most likely find robotic arms and other machines in production processes, even in small and medium-sized businesses (SMBs). This is because the prices of these machines have dropped, enabling most companies to enjoy the economies of scale brought by machines.

Some robotic arms are built to perform simple tasks, while others are made with very intricate parts. Let’s look at some of the basic parts of robotic arms and the roles allocated to these machines in the workplace.

Some of The Basic Parts of Robotic Arms Include:

Actuators

Robotic arms can be fitted with a wide range of actuators. Actuators or, in layman terms, motors are fitted on a robotic arm depending on the scope of motion and bulk of work the robotic arm is supposed to do.

The main types of actuators include:

Servo Motors

A servo motor is an actuator that rotates and allows for precise cutting of pointed or thin parts. The motor is attached to the control framework with bolts, and as the motor turns, the resistance of position sensors will change, and the control framework can induce the rotations.

Stepper Motor

A stepper motor is a DC (direct current) powered electric engine that divides an entire axis into several equal points. The motor can be instructed to change position by moving and stopping at one of these points without needing a sensor so long as the motor is suited to the task it’s performing with regard to speed and thrust.

Linear Actuators

Linear actuators are designed to move in a straight line, and they can be deployed to work in various production settings. Linear actuators move by converting the energy produced by the engine into thrust, which then rotates the tip.

Controllers

Robotic controllers take various forms. In today’s production settings, processes necessitate programs and other components to work together and thereby create a computerized system that can control and check the robotic arm.

Robotic arm control systems fall into various categories Namely:

Pre-Set Control Systems

Pre-set control systems are deployed in less complex robotic arms to repeat their motions and work continuously.

Autonomous Control Systems

Autonomous control systems are fitted in more complex and independent robotic arms, incorporating a couple of sensors and other components that help them recognize and react to changes in their environment.

Sensors

Robotic arms are very comparable to manual operators once they are fitted with sensors. In addition, robotic arms can be incorporated with gadgets that can replicate some human senses such as sight, touch, and smell.

Some of the sensors fitted on robotic arms include; positional sensors, contact sensors, alternation sensors, and distance sensors.

Grippers

A gripper is among the many kinds of components that can be fitted to the limb or end-effector of a robotic arm. A gripper enables the robotic arm to hold objects of varying dimensions and lengths.

Grippers can be moved manually, or they can also have sensors that help them identify the parts they should pick as per the pre-set instructions. Having an automated gripper is vital for production settings such as vehicle assembly that need pick and place of various parts.

Grippers can also be pneumatic or electronically powered. Both of these configurations work well, and their application depends on the production setting and the scope of work the robotic arm will be expected to do.

Which Roles Do Robotic Arms Perform in The Workplace?

Milling

Automated milling is the practice of shredding off bits from a piece to give the piece the proposed design. Robotic arms can execute precise cuts due to the end-effector configuration, which results in quality parts.

Parts of various lengths and widths can be cut, although the components of the end-effector will need to be changed based on the size and material of a piece. Automated milling enables companies to produce numerous quality parts, thereby increasing their profit margins.

Assembly Line

Robotic arms are deployed in an assembly line for modern learning tasks. These machines can unburden manual operators from strenuous and repetitive tasks. These machines can work for long without compromising speed and consistency.

The end-effector can be tailored for various parts so that it can serve various production needs. In addition, the robots can be enhanced by equipping them with vision sensors, improving their precision and efficiency levels.

Welding

Robotic welding can be defined as using powered and programmable devices to completely automate a welding cycle by picking up parts and welding them together.

Robotic welding is a moderately new feature in most production settings. This feature was first introduced in the automobile industry as spot welding.

Today this feature is on the rise in most production settings that require welding. The main objective of robotic welding is to enhance the quality of the weld and decrease some of the mistakes made by manual operators.

Some of the most common types of welding include:

- Spot and arc welding

- Laser welding

- Resistance welding

Material Handling

Material handling robotic arms can automate the most dangerous, complex, and drawn-out tasks in a manufacturing line. Material handling robots will enhance the thruput of the entire production line causing the line to yield high-quality products within the given timeframes. This enables a company to sell more and inspire customer loyalty.

Material handling tasks include various kinds of activities in a company, such as loading raw materials, moving items across the production line, and packing finished items. Companies with large production lines must purchase robots with tremendous speed and payloads.

Final Thought

All in all, a robotic arm is comprised of parts that help the arm to perform some of the roles illustrated above. This will enable companies that use robotic arms to enjoy massive economies of scale and improve their overall yield.

Problem solver. Incurable bacon specialist. Falls down a lot. Coffee maven. Communicator.